Affordable nitrogen gas tank prices for your needs

By:Admin

Established in [], {} has quickly become a leading supplier of nitrogen gas tanks in the industry. The company prides itself on offering a wide range of nitrogen gas tanks that are suitable for various applications, including industrial, medical, and laboratory use. With a strong focus on quality and customer satisfaction, {} has gained a solid reputation for delivering reliable products at cost-effective prices.

In light of the increasing demand for nitrogen gas tanks, {} has been closely monitoring the market trends and making necessary adjustments to ensure that their customers are getting the best value for their money. As a result, the company has recently announced a new pricing strategy for their nitrogen gas tanks, which aims to provide customers with even more competitive prices without compromising on the quality of their products.

The new pricing for {}'s nitrogen gas tanks is a welcome development for many businesses that rely on nitrogen gas for their daily operations. With the cost of nitrogen gas on the rise, finding affordable nitrogen gas tanks has become a top priority for many companies. By offering competitive prices, {} is effectively helping businesses to manage their operational costs and maintain their productivity without breaking the bank.

Moreover, {}'s commitment to delivering high-quality nitrogen gas tanks is a key factor that sets them apart from other suppliers in the market. The company works closely with manufacturers to ensure that their nitrogen gas tanks adhere to the highest industry standards, guaranteeing safe and reliable performance for their customers. This dedication to quality, combined with their new competitive pricing, makes {} a preferred choice for businesses in need of nitrogen gas tanks.

In addition to competitive pricing and top-notch quality, {} also offers a range of services to support their customers, including product installation, maintenance, and technical support. This comprehensive approach to customer service further solidifies {}'s position as a reliable and trusted supplier of nitrogen gas tanks.

As businesses continue to seek cost-effective solutions for their nitrogen gas needs, {} remains committed to providing competitive prices and premium products. With their new pricing strategy, the company is poised to make a positive impact on the market and meet the growing demand for affordable nitrogen gas tanks.

In conclusion, {}'s new pricing for nitrogen gas tanks is a testament to their commitment to providing excellent value to their customers. By offering competitive prices without compromising on quality, the company is well-positioned to meet the needs of businesses across various industries. With their proven track record in the industry and dedication to customer satisfaction, {} is set to be a leading supplier of nitrogen gas tanks for years to come.

Company News & Blog

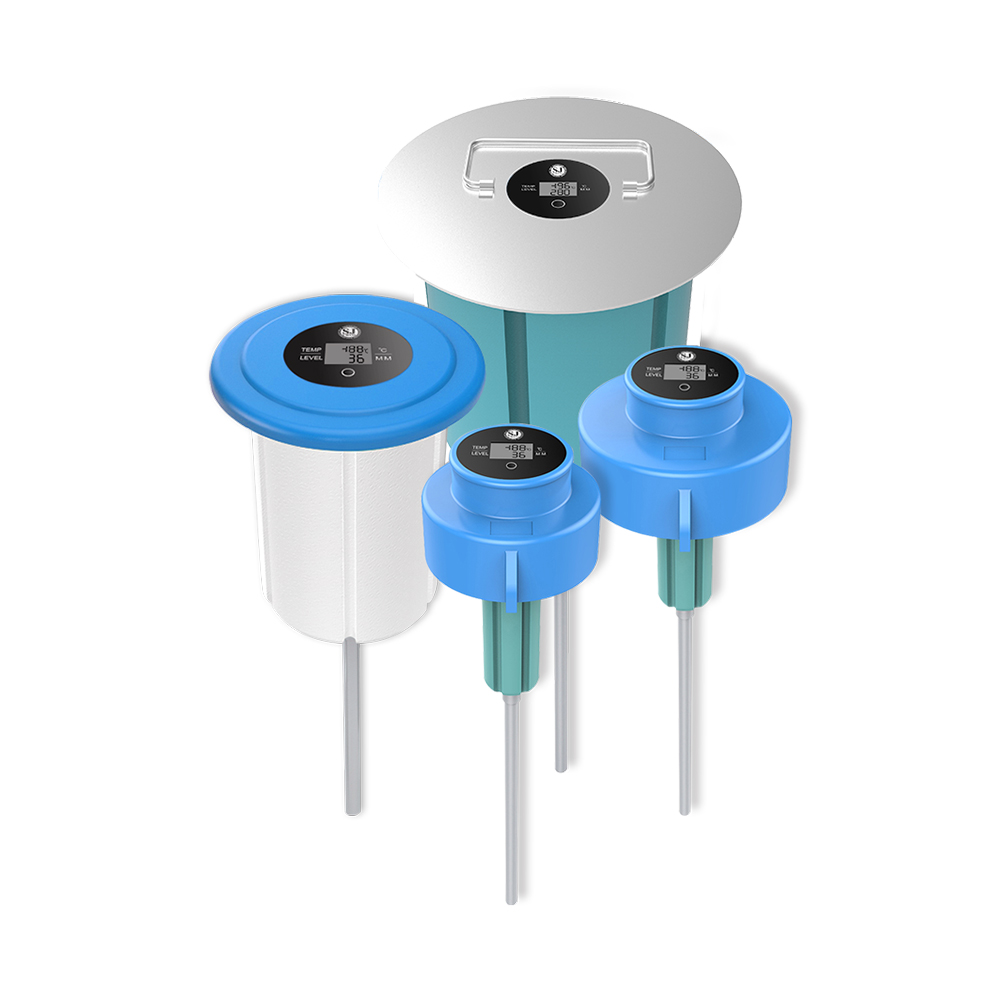

Nitrogen Dewar: The Latest Advancements in Cryogenic Technology

Cryofab has unveiled its latest innovation in cryogenic technology with the introduction of a new nitrogen dewar. This groundbreaking product promises to revolutionize the way cryogenic gases are stored and transported, providing a more efficient and reliable solution for a wide range of industries.The nitrogen dewar is designed to provide a safe and secure means of storing and transporting liquid nitrogen, a critical component in a variety of industrial processes. The dewar features a durable and lightweight construction, making it ideal for use in a wide range of settings. Its advanced insulation technology ensures that the liquid nitrogen remains at the precise temperature required for optimal performance.In addition to its cutting-edge design, the dewar also incorporates several innovative safety features. These include a pressure relief valve, a protective outer shield, and secure locking mechanisms, all of which are designed to minimize the risk of accidents and ensure the safe handling of the cryogenic gas. This makes the nitrogen dewar an ideal choice for companies operating in high-risk industries such as healthcare, pharmaceuticals, and aerospace.Cryofab's nitrogen dewar is also designed with user convenience in mind. It features a user-friendly interface that allows for easy filling and emptying, as well as a compact and portable design that makes it easy to transport and maneuver. This makes it an ideal solution for companies that require a reliable and flexible means of storing and using liquid nitrogen in their day-to-day operations.The introduction of the nitrogen dewar underscores Cryofab's commitment to pushing the boundaries of cryogenic technology. With a long history of innovation in the field of cryogenics, the company has established itself as a leader in the development of cutting-edge solutions for a wide range of industries. The nitrogen dewar represents the latest in a long line of groundbreaking products from Cryofab, and is poised to set a new standard for the storage and transportation of cryogenic gases.The company's dedication to quality and innovation is further evidenced by its rigorous testing and certification processes. The nitrogen dewar has undergone extensive testing to ensure its safety, reliability, and performance, and has been certified to meet the highest industry standards. This commitment to quality and excellence is a hallmark of Cryofab's approach to product development, and is a key reason why the company is trusted by businesses around the world.The release of the nitrogen dewar is expected to have a major impact on a wide range of industries. Companies in the healthcare and pharmaceutical sectors, for example, can benefit from the dewar's ability to safely store and transport liquid nitrogen for use in cryopreservation and medical treatments. Similarly, aerospace and manufacturing companies can take advantage of the dewar's advanced features to streamline their cryogenic processes and improve operational efficiency.In conclusion, the introduction of Cryofab's nitrogen dewar represents a significant milestone in the field of cryogenic technology. With its advanced design, innovative safety features, and user-friendly functionality, the dewar promises to deliver a new level of performance and reliability for companies that rely on cryogenic gases in their operations. As Cryofab continues to push the boundaries of what is possible in cryogenic technology, the nitrogen dewar stands as a testament to the company's commitment to excellence and innovation.

Pressurized liquid nitrogen: What you need to know

Pressurized Liquid Nitrogen Revolutionizing Food Preservation: A Closer Look at {Company}In the world of food preservation, innovation is key. With the growing demand for sustainable and eco-friendly solutions, companies are constantly seeking new methods to extend the shelf life of perishable products without compromising their quality. One such company leading the charge in this arena is {Company}. Their groundbreaking use of pressurized liquid nitrogen has sparked a revolution in the food industry, offering a safe and effective alternative to traditional preservation methods.{Company} was founded in 2010 with a mission to revolutionize food preservation through cutting-edge technology. With a team of expert scientists and engineers, they have developed a proprietary system that harnesses the power of pressurized liquid nitrogen to preserve food products in a way that is both efficient and environmentally friendly.The use of pressurized liquid nitrogen in food preservation is nothing short of a game-changer. Unlike traditional methods such as freezing or canning, which can degrade the quality of the food over time, pressurized liquid nitrogen effectively locks in the freshness and flavor of the product. This is achieved by rapidly cooling the food to extremely low temperatures, inhibiting the growth of microorganisms and slowing down the oxidation process. As a result, the product retains its natural characteristics, making it an attractive option for both consumers and producers alike.One of the key benefits of {Company}'s approach is its ability to reduce food waste. By extending the shelf life of perishable products, they are helping to minimize the amount of food that ends up in landfills. This not only has a positive impact on the environment but also on the bottom line for businesses that rely on effective food preservation to minimize waste and maximize profits.Another advantage of pressurized liquid nitrogen is its versatility. {Company} has successfully applied this technology to a wide range of food products, from fresh fruits and vegetables to dairy and meat. This flexibility has made their preservation method a valuable asset to food producers and manufacturers seeking to maintain the quality and integrity of their products throughout the supply chain.In addition to its preservation capabilities, pressurized liquid nitrogen also offers a safer alternative to chemical preservatives. With consumers becoming increasingly conscious of the ingredients in their food, companies are under pressure to find natural and sustainable solutions. {Company}'s use of pressurized liquid nitrogen aligns with this demand, providing a clean, non-toxic method of preservation that enhances the overall appeal of their products.The success of {Company}'s innovative approach to food preservation has not gone unnoticed. They have attracted attention from major food industry players seeking to collaborate on implementing their technology into existing production processes. This has opened up new opportunities for {Company} to expand their reach and make a greater impact on the industry as a whole.Looking ahead, {Company} remains committed to pushing the boundaries of food preservation technology. They continue to invest in research and development to further enhance their system and explore new applications for pressurized liquid nitrogen. With the potential to revolutionize the way we think about food preservation, {Company} is poised to play a major role in shaping the future of the industry.In conclusion, {Company}'s use of pressurized liquid nitrogen in food preservation is a testament to the power of innovation in addressing critical challenges facing the industry. Their commitment to sustainability, quality, and efficiency has set a new standard for food preservation, and their impact is being felt across the food supply chain. As they continue to push the boundaries of what is possible, it is clear that {Company} is at the forefront of a promising new era in food preservation technology.

Top Quality Cryogenic Dewar Roller Base for Industrial Use

Cryogenic Dewar Roller Base, a revolutionary product from a leading company in the field of cryogenic solutions, is set to transform the way cryogenic dewars are handled and transported. With its advanced technology and innovative design, the Cryogenic Dewar Roller Base provides a safe, efficient, and convenient solution for moving heavy dewars in various settings. Whether it is in a laboratory, industrial facility, or medical institution, this groundbreaking product is designed to meet the diverse needs of different customers.The company behind the Cryogenic Dewar Roller Base is a well-established player in the cryogenic industry, with a strong track record of developing high-quality products that are trusted by customers worldwide. With a team of experienced engineers and technicians, the company has been at the forefront of innovation in the cryogenic field, continuously developing and introducing new technologies to improve the efficiency and safety of cryogenic processes.The Cryogenic Dewar Roller Base is the latest addition to the company's extensive range of cryogenic products and solutions. Equipped with heavy-duty rollers and a sturdy frame, the Roller Base is capable of securely supporting and transporting dewars of various sizes and shapes. Its ergonomic design and smooth maneuverability make it easy for operators to move heavy dewars with minimal effort, reducing the risk of injury and improving overall work efficiency.One of the key features of the Cryogenic Dewar Roller Base is its adaptability to different environments. Whether it is used in a confined laboratory space or a busy industrial setting, the Roller Base is designed to navigate through tight spaces and around obstacles, providing maximum flexibility for users. This versatility makes it an ideal solution for customers who require a reliable and efficient method for handling cryogenic dewars in their daily operations.In addition to its practical design, the Cryogenic Dewar Roller Base is also equipped with safety features to ensure the protection of both the operator and the dewar. The integrated locking mechanisms and stable base provide added security during transportation, minimizing the risk of accidents or spillage. With safety being a top priority for the company, the Roller Base has undergone rigorous testing to meet industry standards and regulations, ensuring its reliability and performance.Furthermore, the company offers customization options for the Cryogenic Dewar Roller Base to meet specific customer requirements. Whether it is a particular size, color, or additional features, the company's engineering team is capable of tailoring the Roller Base to suit the unique needs of individual customers. This customer-centric approach reflects the company's commitment to providing personalized solutions that cater to the diverse demands of the cryogenic industry.The launch of the Cryogenic Dewar Roller Base represents a significant milestone for the company, underscoring its dedication to innovation and continuous improvement in the field of cryogenic technology. As the demand for cryogenic solutions continues to grow across various sectors, the company is poised to play a pivotal role in shaping the future of cryogenic handling and storage.With its cutting-edge technology, superior quality, and unwavering commitment to customer satisfaction, the company has established itself as a leader in the cryogenic industry. The introduction of the Cryogenic Dewar Roller Base further solidifies its position as a trusted provider of innovative and reliable cryogenic solutions. As the company continues to expand its product portfolio and reach new markets, customers can expect more groundbreaking products that will redefine the standards of cryogenic technology.

Unveiling the Breakthrough Nitrogen Tanks That Will Revolutionize the Industry

Title: Mve Nitrogen Tanks: Revolutionizing Cryogenic Storage Solutions Introduction to Mve Nitrogen Tanks:Mve Nitrogen Tanks, developed and manufactured by [company name], have been making significant headlines lately due to their cutting-edge cryogenic storage solutions. With a commitment to excellence, safety, and product innovation, Mve Nitrogen Tanks have been reshaping industries reliant on cryogenic fluids such as medical, research, and food storage facilities. This revolutionary product offers unparalleled performance and durability, ensuring the preservation and safety of valuable samples, medicines, and perishable products.[Company Name] has been a pioneer in the field of cryogenic storage since its inception. Their expertise in engineering, combined with a deep understanding of customer needs, has resulted in the creation of the highly acclaimed Mve Nitrogen Tanks. This product is a testament to the company's dedication to quality and their commitment to serving industries requiring cryogenic storage options.Key Features and Benefits:Mve Nitrogen Tanks boast a variety of unique features and benefits, making them the go-to choice for organizations and individuals seeking reliable cryogenic storage solutions. Some key aspects of Mve Nitrogen Tanks include:1. State-of-the-art Design: Mve Nitrogen Tanks are designed with precision to ensure superior performance and minimal maintenance. The tanks incorporate advanced insulation technologies and high-quality materials, resulting in efficient gas retention.2. Industry-Leading Durability: These tanks are built to withstand extreme temperatures and harsh environments, providing robust and reliable cryogenic storage options. The robust construction ensures long-lasting durability, saving both time and money for businesses.3. Enhanced Safety Features: Mve Nitrogen Tanks prioritize safety by integrating numerous safety features, including pressure and overfill protection systems. These features help prevent accidents and potential leaks, making them ideal for storing sensitive and hazardous materials.4. Easy Accessibility: The tanks come with user-friendly controls that facilitate easy monitoring and accessibility. Features like ergonomic handles, digital temperature displays, and low liquid nitrogen alarm systems ensure seamless functionality and effortless handling.Applications in Various Industries:Mve Nitrogen Tanks have far-reaching applications, catering to a wide range of industries seeking reliable cryogenic storage solutions. Here are some prominent sectors that benefit from Mve Nitrogen Tanks:1. Medical and Biotechnology: The healthcare industry, including hospitals and research institutions, heavily relies on Mve Nitrogen Tanks for the storage of biological samples, vaccines, and cell cultures. The tanks' effectiveness in preserving the efficacy of these critical components plays a vital role in scientific breakthroughs and medical advancements.2. Food and Beverage: The food and beverage industry necessitates precise temperature control to maintain the quality and safety of perishable products. Mve Nitrogen Tanks ensure extended shelf life for frozen foods, preventing bacterial growth and preserving the taste, texture, and nutritional value of the stored items.3. Research and Development: Laboratories and academic institutions utilize Mve Nitrogen Tanks to store valuable research materials such as DNA samples, enzymes, chemicals, and lab-scale cell cultivation. The reliability of these tanks is crucial in supporting scientific advancements and breakthrough discoveries.4. Industrial Applications: Various industrial sectors, including aerospace, automotive, and electronics, rely on Mve Nitrogen Tanks for component preservation, maintenance, and testing. The tanks' ability to retain gas for extended periods ensures the integrity of critical components, increasing operational efficiency and reducing downtime.Conclusion:Mve Nitrogen Tanks, developed by [company name], have emerged as game-changers in the field of cryogenic storage. With their cutting-edge design, durability, and plethora of features, these tanks have revolutionized cryogenic storage solutions across various industries. The commitment to safety and constant innovation sets Mve Nitrogen Tanks apart as the go-to choice for businesses and institutions seeking efficient and reliable storage options for valuable samples, medicines, and perishable products. As we move towards a future heavily reliant on preserving sensitive materials, Mve Nitrogen Tanks remain at the forefront of delivering exceptional storage solutions.

Understanding the Pressure of Liquid Nitrogen Tanks: What You Need to Know

Liquid Nitrogen Tank Pressure Threatens Worker Safety: Company {} Under ScrutinyIn recent news, the safety of workers at a major company has come under scrutiny due to concerns over the high pressure and potential risks associated with liquid nitrogen tanks. The company, known for its innovative approach to technology and research, has faced increasing pressure from regulators and the public to address these safety concerns.Liquid nitrogen is a commonly used chemical in a variety of industrial processes, including freezing and preserving biological samples, as well as cooling and refrigeration. It is stored in tanks at extremely low temperatures, which can reach as low as -320 degrees Fahrenheit. While liquid nitrogen is generally considered safe when handled properly, the high pressure inside the tanks poses a significant risk to workers if not managed effectively.The pressure inside a liquid nitrogen tank is crucial to maintaining the substance in its liquid state. If the pressure inside the tank becomes too high, it can lead to a dangerous buildup of pressure, potentially resulting in a catastrophic failure of the tank. This could cause the release of the extremely cold liquid nitrogen, leading to severe frostbite or asphyxiation if workers are not adequately protected.In response to these concerns, the company has stated that it is committed to the safety and well-being of its employees. The company has implemented several measures to address the pressure issues with their liquid nitrogen tanks, including conducting regular inspections and maintenance of the tanks to ensure that they are operating within safe limits.Additionally, the company has invested in advanced pressure monitoring and control systems to better manage the pressure inside the tanks. These systems allow for real-time monitoring of the tank pressure and can immediately alert workers if the pressure exceeds safe levels, allowing them to take corrective action before a potential safety hazard occurs.Furthermore, the company has provided comprehensive training to its employees on the safe handling and operation of liquid nitrogen tanks. This includes proper procedures for filling, venting, and relieving pressure in the tanks to minimize the risk of accidents or injuries.Despite these efforts, concerns remain about the overall safety culture within the company. Critics argue that the company has not done enough to address the root causes of the pressure issues with its liquid nitrogen tanks. They assert that a lack of proper maintenance and oversight has contributed to the unsafe conditions for workers and call for more stringent regulations and oversight.In response, the company has vowed to continue working closely with regulators and safety experts to address these concerns. They have expressed a commitment to improving their safety protocols and ensuring that their employees are adequately protected from the potential risks associated with liquid nitrogen tanks. The company also plans to conduct a comprehensive review of its safety practices and make any necessary changes to further mitigate the risks.While the company's reputation has been called into question in light of these safety concerns, they remain a leader in the industry and are known for their cutting-edge research and technology. However, the issue of worker safety is a critical one that cannot be overlooked, and it is essential for the company to take swift and decisive action to address these concerns and ensure the well-being of its employees.As the company continues to navigate these challenges, it is clear that there is a pressing need for a renewed focus on safety and a commitment to upholding the highest standards in the industry. Only through a concerted effort to address the issues at hand can the company regain the trust and confidence of its employees, regulators, and the public. It remains to be seen how the company will ultimately respond to these concerns and whether they will be able to effectively mitigate the risks associated with their liquid nitrogen tanks. However, one thing is certain – the safety of their workers must be their top priority.

Innovative Approaches to Cryogenic Storage and Liquid Terminal Projects

and design, liquid terminal projects, and innovative approaches to construction.Cryogenic storage and liquid terminal projects require specialized expertise and innovative solutions to ensure safe and efficient storage and handling of materials. As an engineering procurement and construction (EPC) company, IHI E&C has the capability and experience to deliver turnkey solutions for these projects.Our expertise in cryogenic tank construction and design allows us to provide customized solutions for our clients. We have a full in-house team of designers and engineers who work together to ensure that the tanks meet or exceed the client’s specifications. From initial design to final commissioning, we have a proven track record of delivering quality projects on time and within budget.One of the key advantages of working with IHI E&C is our innovative approach to construction. We leverage the latest technologies and construction methods to streamline the construction process and reduce costs. Our efficient construction methods not only save time and money, but they also result in a higher quality product.To ensure that our projects are completed with the highest level of quality, we have implemented a comprehensive quality management system. Our quality management system covers all aspects of the project including design, construction, and commissioning. By following strict quality guidelines, we can ensure that the end product meets or exceeds the client’s expectations.In addition to cryogenic tank construction and design, we also specialize in liquid terminal projects. Our experience in this field allows us to deliver turnkey solutions for liquid storage and handling facilities. We work closely with our clients to understand their specific needs and design customized solutions that meet those needs.At IHI E&C, we are committed to providing innovative solutions for our clients. By leveraging our expertise in cryogenic tank construction and design, liquid terminal projects, and innovative construction methods, we can deliver turnkey solutions that meet or exceed our client’s expectations. Contact us today to learn more about how we can help with your next project. Keywords: cryogenic tank construction, cryogenic tank design, liquid terminal projects, innovative approaches to construction.

High-Quality Solid Liquid Nitrogen Tank for Sale in the US

US Company Revolutionizes Storage with New Solid Liquid Nitrogen TankIn recent years, the demand for reliable and efficient cryogenic storage solutions has been on the rise. The need for safe and secure storage of biological samples, pharmaceuticals, and other temperature-sensitive materials has led to advancements in cryogenic technology. One company at the forefront of these advancements is [Company Name], a leader in the development of cryogenic storage solutions.[Company Name] has recently introduced a groundbreaking product that is set to revolutionize the industry - the Solid Liquid Nitrogen Tank. This innovative storage tank utilizes a state-of-the-art design and advanced materials to provide unmatched performance and reliability for the storage of cryogenic materials.The Solid Liquid Nitrogen Tank is engineered to maintain a stable and ultra-low temperature environment, ensuring the safe preservation of biological samples, pharmaceuticals, and other sensitive materials. This is achieved through the use of advanced insulation materials and a robust, double-walled construction that minimizes heat transfer and maintains temperature stability.One of the key features of the Solid Liquid Nitrogen Tank is its unique solid-state cooling system. Unlike traditional liquid nitrogen tanks, which rely on the continuous supply of liquid nitrogen to maintain temperature, this new system uses a solid nitrogen source that is capable of maintaining ultra-low temperatures for extended periods of time. This not only reduces the frequency of nitrogen refills but also provides a more stable and reliable storage environment for sensitive materials.Another significant advantage of the Solid Liquid Nitrogen Tank is its compact and space-saving design. The tank is available in a range of sizes, making it suitable for a variety of storage needs while minimizing the required footprint. This makes it an ideal solution for laboratories, research facilities, and pharmaceutical companies where space is at a premium.[Company Name] prides itself on delivering high-quality and reliable products, and the Solid Liquid Nitrogen Tank is no exception. Each tank is manufactured to the highest standards, using premium materials and advanced manufacturing techniques to ensure long-lasting performance and durability. Additionally, the tank is equipped with a range of safety features to provide peace of mind for users, including pressure relief valves, protective coatings, and secure locking mechanisms.The introduction of the Solid Liquid Nitrogen Tank represents a significant milestone for [Company Name]. The company has a long history of innovation in the field of cryogenic storage solutions, and this new product further solidifies its position as a leader in the industry. With its unparalleled performance, reliability, and safety features, the Solid Liquid Nitrogen Tank is set to become the go-to choice for organizations seeking cutting-edge cryogenic storage solutions."We are thrilled to introduce the Solid Liquid Nitrogen Tank to the market," said [Spokesperson], CEO of [Company Name]. "This product is the result of years of research and development, and we believe it will make a significant impact on the industry. We are confident that the Solid Liquid Nitrogen Tank will set a new standard for cryogenic storage, providing our customers with a reliable and efficient solution for their storage needs."In conclusion, [Company Name] has once again demonstrated its commitment to innovation and excellence with the introduction of the Solid Liquid Nitrogen Tank. With its advanced design, solid-state cooling system, space-saving design, and top-notch safety features, this new product is set to redefine the standards for cryogenic storage solutions. As the demand for reliable and efficient cryogenic storage continues to grow, the Solid Liquid Nitrogen Tank is poised to meet the needs of a wide range of industries, providing a secure and dependable solution for the storage of temperature-sensitive materials.

Large Liquid Storage Tank in China Experiences Record Growth

China Liquid Storage Tank, a leading manufacturer in the industry, has recently announced a breakthrough in liquid storage technology. The company, which prides itself on innovation and quality, has developed a new storage tank that is set to revolutionize the industry.The new liquid storage tank, which the company has named the X1, is a result of years of research and development. It is designed to address the challenges faced by traditional storage tanks, such as corrosion, leakage, and environmental impact. The X1 is constructed using state-of-the-art materials and manufacturing processes, making it durable, reliable, and environmentally friendly.One of the key features of the X1 is its corrosion-resistant design. The tank is coated with a special material that prevents corrosion, extending its lifespan and reducing maintenance costs. This is a significant advancement in the industry, as corrosion has been a major issue for liquid storage tanks for many years.In addition to its corrosion resistance, the X1 also features a leak-proof design. The tank is equipped with advanced sealing technology that ensures no liquid can escape, providing peace of mind to users and minimizing the risk of environmental contamination.Furthermore, the X1 is designed with environmental sustainability in mind. The materials used in its construction are recyclable, and the tank is designed to minimize its environmental impact throughout its lifecycle. This reflects China Liquid Storage Tank's commitment to sustainability and responsible manufacturing practices.The X1 is available in a range of sizes to suit different storage needs, making it a versatile solution for a variety of industries. Whether it is for storing water, chemicals, or petroleum products, the X1 offers a reliable and efficient storage solution.According to the company's spokesperson, the X1 has undergone rigorous testing to ensure its quality and performance. They expressed confidence in the product, stating that it will set a new standard for liquid storage tanks in the industry.The announcement of the X1 has generated excitement and anticipation in the market. Industry experts and potential customers are eager to see how this new technology will impact the liquid storage industry. Many are expecting the X1 to become the new benchmark for liquid storage tanks, raising the bar for quality, reliability, and environmental sustainability.China Liquid Storage Tank has established itself as a leader in the industry, with a strong track record of delivering high-quality products and innovative solutions. The company has a dedicated team of engineers and technical experts who are committed to pushing the boundaries of liquid storage technology.The development of the X1 is a testament to the company's vision and commitment to excellence. It demonstrates their willingness to invest in research and development to create products that meet the evolving needs of the market and drive positive change in the industry.As China Liquid Storage Tank continues to grow and expand its product offerings, the introduction of the X1 marks a significant milestone for the company. It reinforces their position as a forward-thinking and customer-centric organization, dedicated to delivering cutting-edge solutions that make a real difference.In conclusion, the introduction of the X1 liquid storage tank by China Liquid Storage Tank represents a significant advancement in the industry. With its corrosion-resistant design, leak-proof technology, and commitment to environmental sustainability, the X1 is set to redefine the standards for liquid storage tanks. As the company continues to innovate and push boundaries, it is clear that they are at the forefront of driving positive change in the industry. The X1 is not just a new product – it is a reflection of China Liquid Storage Tank's unwavering commitment to excellence and innovation.

Get Lightweight and Efficient Liquid Nitrogen Dewar Flasks for Safe Cryogen Storage and Transfer

Flasks, Cryogenic Storage, Custom Biogenics, Lightweight Dewars, Efficient Liquid Nitrogen TransferLiquid-nitrogen dewar flasks are essential tools for cryogenic storage and transfer. They are commonly used in research laboratories, medical facilities, and industrial settings to store and transport materials at extremely low temperatures. With the increasing demand for safe and efficient cryogen storage, Custom Biogenics has introduced a range of lightweight and efficient liquid-nitrogen dewars that offer unrivaled performance and convenience. This blog will discuss the benefits of the Custom Biogenics liquid-nitrogen dewars and why they are the perfect solution for your cryogenic storage needs.Custom Biogenics is a leading manufacturer of cryogenic storage systems and accessories. They have been in the business for over thirty years and have established themselves as the go-to source for high-quality and reliable cryogenic equipment. Their products are designed and built to meet the highest industry standards and are used by researchers, medical professionals, and industrial companies around the world.The 4 Liter Liquid Nitrogen Dewar Flask is a standout product in Custom Biogenics' line of liquid-nitrogen dewars. It is lightweight, durable, and offers superior performance and convenience. The flask features a double-walled vacuum design that ensures maximum thermal insulation, which effectively minimizes the loss of liquid nitrogen during storage and transportation. The 4-liter size is perfect for smaller applications, making it ideal for researchers and small laboratories.One of the key advantages of the Custom Biogenics liquid-nitrogen dewars is their efficiency. The double-walled vacuum design not only minimizes the loss of liquid nitrogen, but it also reduces the amount of nitrogen gas produced during storage. This makes the dewars more economical to use and helps to preserve the environment. Furthermore, the dewars are equipped with a sturdy carrying handle that makes it easy to transport them from one location to another.Safety is a top priority when it comes to cryogenic storage and transfer, and Custom Biogenics has taken this into account when designing their liquid-nitrogen dewars. The flasks feature a pressure relief valve that ensures safe venting of excess gas in case of accidental over-pressurization. They are also equipped with a protective cover that shields the dewars from potential damage during handling and transportation.In addition to being safe and efficient, the Custom Biogenics liquid-nitrogen dewars are also convenient to use. They are compatible with a wide range of accessories, including canisters, racks, and liquid nitrogen withdrawal equipment. This makes it easy to customize the dewars to suit your specific requirements. The dewars are also easy to clean and maintain, thanks to their simple design and high-quality construction.In conclusion, if you are in the market for a reliable and efficient liquid-nitrogen dewar, the Custom Biogenics 4 Liter Liquid Nitrogen Dewar Flask is an excellent choice. Its lightweight design, superior performance, and safety features make it the perfect solution for your cryogenic storage needs. With the ability to store and transfer materials at extremely low temperatures, you can be sure that your samples and specimens will be safe and secure. Place your order today and experience the convenience and reliability of the Custom Biogenics liquid-nitrogen dewars.

Top Machine Manufacturer Produces Latest Technology for Market

[Name of the Machine Manufacturer] Unveils Cutting-Edge N2 Machine[City, Date] - [Name of the Machine Manufacturer], a leading provider of industrial machinery, has unveiled its latest innovation - the N2 machine. This state-of-the-art machine is set to revolutionize the manufacturing industry with its advanced capabilities and unparalleled performance.The N2 machine is designed to meet the increasing demands of modern manufacturing processes by offering a wide range of features and functionalities. With its robust construction and precision engineering, the N2 machine is capable of delivering high levels of accuracy, efficiency, and reliability. This makes it ideal for a wide range of applications across various industries, including automotive, aerospace, electronics, and more.With a focus on innovation and quality, [Name of the Machine Manufacturer] has been at the forefront of the industrial machinery industry for several years. The company has a strong track record of delivering cutting-edge solutions that help businesses increase productivity, reduce costs, and improve overall efficiency.The introduction of the N2 machine is another testament to [Name of the Machine Manufacturer]'s commitment to pushing the boundaries of what is possible in manufacturing technology. By leveraging the latest advancements in engineering and automation, the N2 machine offers a level of performance that is unmatched by any other machine in its class.One of the key features of the N2 machine is its advanced control system, which allows for seamless integration with other manufacturing equipment and processes. This enables businesses to optimize their production workflows and achieve higher levels of automation, resulting in increased output and reduced downtime.Additionally, the N2 machine is equipped with a range of safety features to ensure the well-being of operators and workers in the manufacturing environment. This includes advanced monitoring systems, emergency stop protocols, and comprehensive training resources to help businesses maintain a safe and secure workplace.Furthermore, [Name of the Machine Manufacturer] provides comprehensive support and maintenance services for the N2 machine, ensuring that businesses can maximize the potential of their investment. This includes regular inspections, software updates, and 24/7 technical assistance to address any issues that may arise.In a statement, [Name of the Machine Manufacturer] CEO expressed their excitement about the launch of the N2 machine, stating: "We are proud to introduce the N2 machine to the market, as it represents the culmination of our dedication to innovation and excellence. We believe that this machine will empower businesses to achieve new levels of productivity and competitiveness, and we are committed to supporting our customers every step of the way."The N2 machine is now available for purchase, and [Name of the Machine Manufacturer] is offering demonstrations and consultations to businesses interested in learning more about its capabilities. With its cutting-edge technology and comprehensive support, the N2 machine is poised to become a game-changer for the manufacturing industry.For more information about the N2 machine and other industrial machinery solutions from [Name of the Machine Manufacturer], visit their website at [Website].About [Name of the Machine Manufacturer]:[Name of the Machine Manufacturer] is a leading provider of industrial machinery, specializing in advanced solutions for various manufacturing processes. With a commitment to innovation and quality, [Name of the Machine Manufacturer] has established itself as a trusted partner for businesses seeking to improve their production capabilities and efficiency. For more information, visit [Website].