Nitrogen Tank for Sperm: Importance and Use in Fertility Preservation

By:Admin

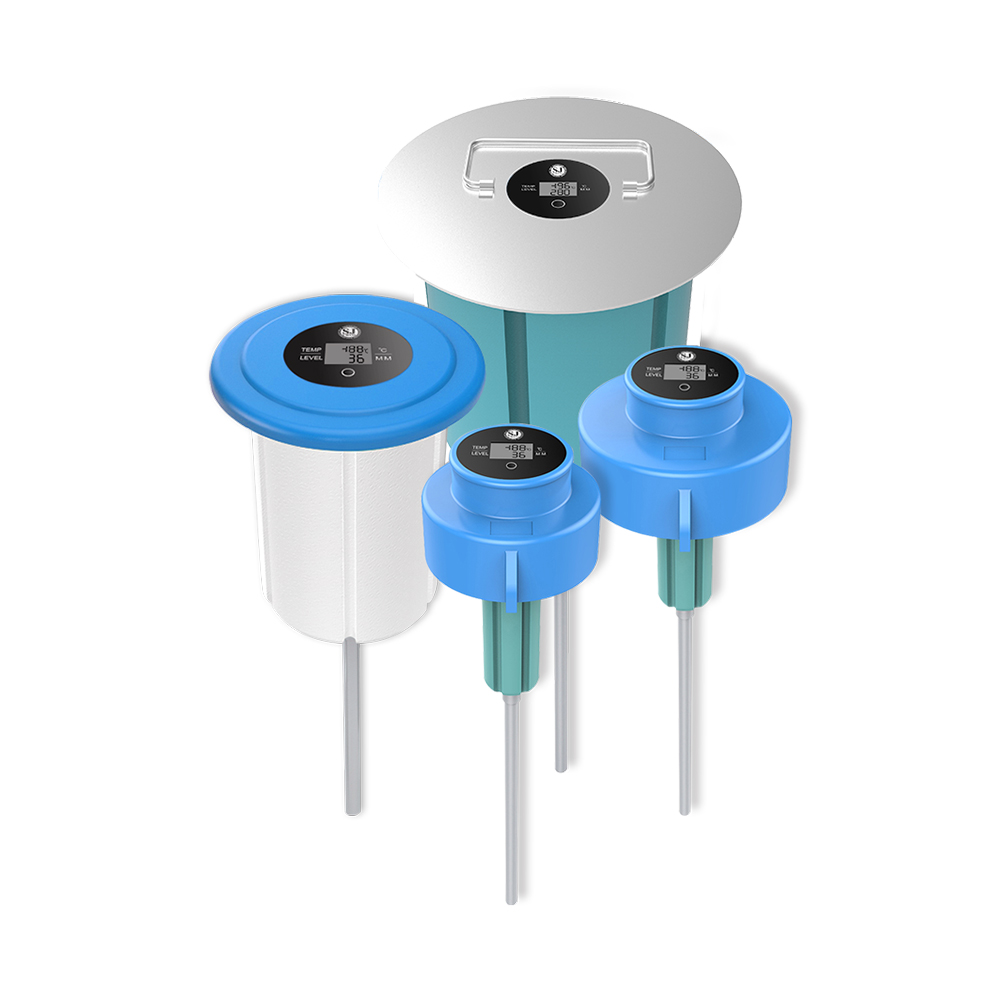

The nitrogen tank, which has been developed by the company's team of expert scientists and engineers, is designed to provide an optimal environment for the long-term storage of sperm samples. With its advanced temperature control and preservation capabilities, the nitrogen tank ensures the integrity and viability of sperm samples over extended periods of storage. This means that individuals and couples looking to preserve their fertility for future use can now have full confidence in the quality and viability of their stored sperm samples.

The company's nitrogen tank for sperm storage has been meticulously developed and tested to meet the highest standards of quality and reliability. Its cutting-edge features include precise temperature regulation, advanced cryopreservation technology, and enhanced security and monitoring systems. These features work in synergy to maintain the viability of sperm samples, ensuring that they remain viable for use in assisted reproductive procedures whenever the need arises.

One of the key advantages of the company's nitrogen tank for sperm storage is its user-friendly design and intuitive interface. This makes it easy for healthcare professionals and laboratory technicians to access and manage stored sperm samples with ease and efficiency. Additionally, the nitrogen tank is equipped with comprehensive tracking and monitoring systems, providing real-time data on the status and condition of stored sperm samples. This ensures that healthcare providers can maintain optimal conditions for sperm storage and ensure the highest level of quality and safety for preserved samples.

The introduction of this advanced nitrogen tank for sperm storage underscores the company's commitment to advancing the field of reproductive technology and providing cutting-edge solutions for fertility preservation. The company has a long-standing reputation for excellence in developing innovative products and services that address the diverse needs of individuals and couples seeking to preserve their fertility and achieve their reproductive goals.

In addition to its revolutionary nitrogen tank for sperm storage, the company offers a comprehensive range of services related to fertility preservation and assisted reproductive technology. This includes sperm freezing, egg freezing, embryo preservation, and a variety of other advanced reproductive solutions. The company's team of experts includes leading scientists, fertility specialists, and healthcare professionals who are dedicated to providing the highest level of care and support for individuals and couples on their reproductive journey.

The launch of the company's nitrogen tank for sperm storage represents a major milestone in the field of fertility preservation and assisted reproductive technology. With its advanced features and cutting-edge capabilities, this innovative technology is set to have a transformative impact on the way sperm samples are stored and preserved for future use. By providing a reliable and secure solution for sperm storage, the company is empowering individuals and couples to take control of their reproductive health and achieve their dreams of building a family.

As the company continues to lead the way in developing advanced solutions for fertility preservation and reproductive health, it is poised to make a significant contribution to the field of assisted reproductive technology. With its unwavering commitment to excellence and innovation, the company is set to shape the future of reproductive technology and empower individuals and couples to embrace the possibilities of parenthood.

Company News & Blog

Top liquid nitrogen storage boxes for your needs

The demand for safe and efficient storage solutions has never been greater, especially in industries that rely on cryogenic materials such as medical, pharmaceutical, and research fields. With this in mind, one company has been at the forefront of providing innovative solutions for liquid nitrogen storage. Their cutting-edge technology and commitment to quality have set them apart as a leader in the industry.{Company} has been a trailblazer in the development and manufacturing of liquid nitrogen storage boxes. These boxes are designed to safely and securely store cryogenic materials at ultra-low temperatures, ensuring that the integrity of the samples is maintained at all times. With a strong focus on research and development, the company has continuously refined and improved its storage solutions to meet the evolving needs of its customers.One of the key features of {Company}'s liquid nitrogen storage boxes is their robust construction. Made from high-quality materials, these boxes are built to withstand the extreme temperatures required for cryogenic storage. This not only ensures the safety of the samples but also extends the lifespan of the storage boxes, providing long-term value for customers.In addition to their durability, {Company}'s storage boxes also offer unparalleled insulation. This is critical for maintaining the stability and viability of the stored samples, especially in applications where even the slightest temperature fluctuations can compromise the integrity of the materials. With {Company}'s storage boxes, customers can have peace of mind knowing that their cryogenic materials are being kept at the optimal conditions for maximum preservation.Furthermore, {Company} has leveraged its expertise in cryogenic storage to develop innovative features that enhance the usability and efficiency of its storage boxes. From advanced locking mechanisms to ergonomic designs, every aspect of the boxes has been carefully considered to make them as user-friendly as possible. This attention to detail has made {Company}'s storage boxes a popular choice among researchers, medical professionals, and pharmaceutical companies alike.What sets {Company} apart from its competitors is its unwavering commitment to quality and customer satisfaction. The company takes pride in its ability to deliver tailored solutions that meet the unique requirements of its clients. Whether it's custom sizing, specialized features, or bulk orders, {Company} has the expertise and flexibility to accommodate a wide range of needs, making it a trusted partner for businesses and organizations across various industries.Another standout aspect of {Company}'s approach is its dedication to environmental sustainability. In an era where eco-friendly practices are increasingly prioritized, {Company} has made significant efforts to minimize its environmental impact. From using recyclable materials in the manufacturing process to optimizing energy efficiency in its facilities, the company is committed to being a responsible steward of the environment.Looking ahead, {Company} is poised to continue its leadership in the liquid nitrogen storage market. With ongoing investments in research and development, as well as a steadfast commitment to quality and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and drive innovation in the industry. As the demand for cryogenic storage solutions continues to grow, {Company} is ready to meet the challenge and exceed expectations with its cutting-edge technology and unwavering dedication to excellence.

Nitrogen Cylinder Filling: An Essential Guide for Efficient Operations

Title: Nitrogen Cylinder Filling: Streamlining Industrial Processes for Enhanced EfficiencyIntroduction: Industrial processes often require the use of various gases to ensure smooth operations and maintain product quality. Nitrogen, in particular, plays a crucial role in diverse industries ranging from food packaging to electronics manufacturing. Today, we direct our attention towards a pioneering company that specializes in nitrogen cylinder filling, revolutionizing the way industries access this vital gas.[Company Name], a respected industry leader known for its commitment to excellence, has harnessed advanced technologies and established a robust infrastructure to meet the growing demand for nitrogen cylinder filling services. In this article, we will explore the significance of nitrogen, understand the wide range of industries it benefits, and delve into the exemplary solutions provided by [Company Name].The Importance of Nitrogen:Nitrogen, a colorless and odorless gas, acts as an inert blanket in various industrial processes. Its non-reactive nature makes it ideal for preserving freshness, preventing oxidation, and inhibiting the growth of bacteria. Nitrogen is widely employed in the food industry for packaging snacks, cereals, and perishable goods to extend their shelf life. Moreover, this gas is instrumental in promoting safe aircraft fueling, reducing the risk of combustion and enhancing aviation safety.Applications in Diverse Industries:1. Food and Beverage: Nitrogen is used extensively in the food and beverage industry to improve product quality and prolong shelf life. It is utilized in modified atmosphere packaging (MAP) processes, where nitrogen replaces oxygen in sealed containers to prevent spoilage caused by oxidation.2. Electronics: Nitrogen’s moisture-free and non-reactive properties make it indispensable in the electronics industry. It is used during soldering processes to prevent oxidation and enhance the durability of electronic components. Nitrogen also facilitates the manufacturing of semiconductors, preventing contamination and ensuring high-quality standards.3. Oil and Gas: Nitrogen is employed in oil and gas exploration and production, removing the need for oxygen-rich environments and preventing the occurrence of explosions during drilling processes. Additionally, it is used for pressure testing pipelines and equipment, ensuring their safety and reliability.4. Chemical Manufacturing: Nitrogen plays an essential role in various chemical manufacturing processes. It is used for tank blanketing, purging, and drying equipment, preventing reactions caused by exposure to oxygen or moisture. Nitrogen also aids in the safe handling and transportation of hazardous chemicals, reducing the risk of accidents.Revolutionizing Nitrogen Cylinder Filling:[Company Name], a pioneering player in the field of nitrogen cylinder filling, offers innovative and cost-effective solutions to industries across the spectrum. Leveraging their state-of-the-art facilities and cutting-edge technologies, they ensure that customers receive pure and reliable nitrogen cylinders tailored to their specific requirements.1. Advanced Filling Techniques: [Company Name] utilizes advanced filling techniques, such as cryogenic liquid nitrogen delivery and high-pressure nitrogen filling. These methods guarantee precise pressure control, enabling customers to optimize their operations and achieve optimal results in their applications.2. Quality Assurance: [Company Name] adheres to stringent quality control measures throughout the nitrogen cylinder filling process. They employ rigorous testing and analysis to ensure the purity and consistency of nitrogen delivered to their clients. By utilizing industry-leading practices, [Company Name] sets the benchmark for reliability and excellence in the nitrogen cylinder filling domain.3. Customized Solutions: Understanding that different industries have unique nitrogen requirements, [Company Name] offers customized solutions tailored to customer needs. Whether it is providing cylinders with specific pressure requirements, sourcing nitrogen from special sources, or assisting with application-specific setups, their expertise ensures streamlined operations for enhanced efficiency.Conclusion:As industries continue to evolve and demand higher standards of efficiency, the significance of nitrogen in various industrial processes cannot be overstated. [Company Name] has emerged as a trailblazer, revolutionizing nitrogen cylinder filling services by combining advanced technologies, stringent quality control, and bespoke solutions. With their unwavering commitment to excellence, [Company Name] is paving the way for optimized operations, increased productivity, and enhanced safety for industries that rely on this vital gas.

EU Pressure to Increase Transparency in Liner Companies Gives Shippers Hope

Shipping companies are increasingly facing pressure from shippers to become more transparent in their operations. This is because many shippers feel that they do not have enough information about what is happening with their cargo when it is being transported by these companies.One of the main concerns for shippers is the concentration of power among liner companies. This is making it difficult for them to negotiate favourable deals and prices. They also feel that this concentration is leading to less competition, which is affecting the quality of service they receive.Shippers are now hoping that the EU can help to force through changes in the industry. Specifically, they are calling for more transparency and accountability from shipping companies. This would include things like more detailed tracking of shipments and better communication with customers.In order to achieve this, shippers are calling for the introduction of mandatory regulations that would require liner companies to provide more information about their operations. They are also calling for more competition in the industry, which would force companies to improve their services in order to stay competitive.One area where shippers are particularly concerned is the use of dry shipper containers. These containers are designed to keep goods dry during transport, but there is concern that they are not always being used properly. Shippers are calling for more information about how these containers are being used and what measures are being taken to ensure that they are working correctly.Overall, shippers are calling for a more open and transparent industry. They believe that this will not only benefit them, but also the shipping companies themselves. By providing better information and services, these companies will be able to build stronger relationships with their customers and improve their bottom line.

Container Manufacturer in Germany - Container Sales and Trading Across Europe | Mobile Hybrid Containers for COVID-19 Vaccines | Buy New or Used Sea Containers Worldwide | Tractors for Internal Transport | Insulated Storage Containers | Discounted Construction Site Containers | 20ft Flat Rack Containers

In response to the COVID-19 pandemic, German company MECOTEC Group has launched a one-stop solution for the transport, storage, and distribution of vaccines with its first Mobile Hybrid Container. This innovative product offers deep-freeze capabilities and can be easily transported to different locations. For those in need of storage or transport containers, several companies offer a variety of options. SCHÄFER Container Systems is a major container manufacturer while HaCoBau - Hallen- und Containersysteme GmbH offers a range of products including material and insulated storage containers. Sea and Shipping Containers provides new and used sea containers worldwide, and MT Container offers flats, building, and discount containers. For internal transport in seaports, industry, logistics, and distribution centers, MAFI Transport-Systeme GmbH produces tractors while CONTAINEX provides sea containers. In summary, there is a wide array of options for those needing containers for storage, transport, or even specialized products like the MECOTEC Mobile Hybrid Container that can facilitate vaccine distribution. Whether you need standard sea containers, insulated storage containers, or building and flat containers, there are many options to choose from.

Key Considerations for Nitrogen Storage Tank Design

Nitrogen Storage Tank Design Revolutionizes Industrial Gas StorageThe industrial gas industry has always been in constant search for innovative solutions in gas storage. The quest for a safer, more efficient, and cost-effective nitrogen storage tank design has led to the groundbreaking development of a new storage system by {company name}.{Company name} is a leading industrial gas company, dedicated to providing high-quality gases and storage solutions to a wide range of industries, including manufacturing, electronics, healthcare, and research laboratories. With a commitment to innovation and excellence, the company has continued to invest in research and development to revolutionize the way industrial gases are stored and utilized.The latest breakthrough from {company name} is a nitrogen storage tank design that incorporates cutting-edge technology and advanced materials to address the challenges of traditional storage systems. The new design offers a significant improvement in safety, efficiency, and reliability, making it an ideal solution for industrial gas users.One of the key features of the new nitrogen storage tank design is its enhanced safety measures. The tank is built with robust construction and advanced safety mechanisms to prevent leaks, pressure buildup, and other potential hazards. This ensures that the stored nitrogen gas is securely contained, minimizing the risk of accidents and enhancing workplace safety.In addition to safety, the new storage system also offers improved efficiency in gas storage and distribution. The design incorporates advanced insulation materials and temperature control systems, allowing for better preservation of the nitrogen gas at optimal conditions. This results in reduced gas loss and improved utilization, ultimately leading to cost savings for users.Furthermore, the new nitrogen storage tank design is highly adaptable to various industrial applications. It is available in a range of sizes and configurations to suit different storage capacity requirements, making it suitable for small-scale operations as well as large industrial facilities. This flexibility in design ensures that the storage system can be customized to meet the specific needs of different customers.{Company name} has also emphasized environmental sustainability in the development of the new nitrogen storage tank design. The system is designed to minimize gas emissions and energy consumption, contributing to a greener and more eco-friendly industrial gas storage solution. This aligns with the company's commitment to environmental responsibility and the reduction of its carbon footprint.The introduction of the new nitrogen storage tank design has generated significant interest and positive feedback from the industrial gas community. Customers have expressed enthusiasm for the enhanced safety features, improved efficiency, and environmental benefits offered by the new storage system. Many are eager to adopt the technology to optimize their gas storage and distribution processes.In conclusion, the new nitrogen storage tank design from {company name} represents a significant advancement in the industrial gas storage industry. With its focus on safety, efficiency, adaptability, and sustainability, the new storage system is poised to redefine the standards for nitrogen gas storage and set a new benchmark for industrial gas storage solutions. As {company name} continues to push the boundaries of innovation, the future of industrial gas storage looks promising with the introduction of this groundbreaking technology.

New Liquid Nitrogen Machine in China

China's Liquid N2 Machine Revolutionizes Industrial Cooling TechnologyIn the fast-paced world of industrial manufacturing, innovation is key to stay ahead of the competition. With the ever-increasing demand for efficient and sustainable cooling solutions, companies are constantly on the lookout for cutting-edge technologies that can meet their needs. One such technology that has been making waves in the industry is the Liquid N2 Machine, a revolutionary cooling system developed by a leading Chinese company.The Liquid N2 Machine is designed to provide high-performance cooling for a wide range of industrial applications. By utilizing liquid nitrogen as the cooling agent, this innovative machine is able to achieve lower temperatures than traditional refrigeration systems, making it ideal for processes that require ultra-low temperatures.The potential applications of the Liquid N2 Machine are vast, from food processing and pharmaceutical manufacturing to semiconductor production and chemical processing. With its ability to rapidly cool and maintain precise temperatures, this technology has the potential to revolutionize the way industries approach their cooling needs.The company behind the development of the Liquid N2 Machine is a respected leader in the field of industrial equipment manufacturing. With a strong focus on research and development, the company has a proven track record of delivering innovative and reliable solutions to its customers. Their expertise in precision engineering and dedication to quality has set them apart as a trusted partner for businesses seeking advanced cooling technology.Moreover, the company has a comprehensive service network that ensures their customers receive the support they need to maximize the performance of the Liquid N2 Machine. From installation and training to ongoing maintenance and technical assistance, the company is committed to providing a seamless experience for their clients.In addition to the technical capabilities of the machine, the company also emphasizes the environmental benefits of the technology. By leveraging the use of liquid nitrogen, the Liquid N2 Machine offers a more sustainable alternative to traditional refrigeration systems, reducing energy consumption and greenhouse gas emissions. This aligns with the growing demand for eco-friendly solutions in today's industrial landscape.The launch of the Liquid N2 Machine has already garnered significant attention within the industry, with several businesses expressing interest in adopting this advanced cooling technology. The machine's ability to deliver superior performance while minimizing environmental impact has resonated with companies looking to enhance their operational efficiency and sustainability.One of the key advantages of the Liquid N2 Machine is its modular design, which allows for scalability and customization to suit the specific needs of each customer. Whether it's for small-scale operations or large industrial facilities, this flexibility ensures that the machine can be tailored to meet the unique demands of various industries.As the industry continues to evolve, the demand for advanced cooling solutions will only continue to grow. With the introduction of the Liquid N2 Machine, the Chinese company has demonstrated its commitment to driving innovation and shaping the future of industrial cooling technology. By offering a powerful and sustainable alternative to traditional refrigeration systems, this technology is poised to make a significant impact on the way businesses approach their cooling needs.In conclusion, the Liquid N2 Machine represents a significant advancement in industrial cooling technology, with the potential to transform the way businesses approach their cooling needs. Backed by a reputable company with a strong track record of delivering high-quality solutions, this innovative technology is poised to revolutionize the industry and set new standards for performance and sustainability. With its modular design and environmental benefits, the Liquid N2 Machine has the potential to become a game-changer in the world of industrial manufacturing.

Unveiling Different Sizes of Nitrogen Cylinders - A Comprehensive Guide

In recent news, nitrogen cylinder sizes have become increasingly popular within a variety of industries. The capacity to store and transport nitrogen gas in an efficient manner has made these cylinders a go-to solution for businesses across the globe. Companies that specialize in the production of nitrogen cylinders have seen a significant increase in demand as more and more industries adopt the use of this storage method for their nitrogen gas needs.One such company that has seen a surge in demand for their nitrogen cylinders is {Company Name}. The company has been a major player in the production of nitrogen cylinders for a number of years. Their dedication to providing high-quality, reliable, and affordable nitrogen cylinders has made them a trusted name within the industry.With a range of nitrogen cylinder sizes available, {Company Name} is able to accommodate a vast array of requirements from their customers. From small, portable cylinders that can be transported easily, to larger cylinders that can store a significant amount of gas – their product line is versatile and adaptable to the needs of any business.One of the key benefits of using nitrogen gas stored within cylinders is that it can be used for a variety of applications, from food preservation to fire suppression systems. Nitrogen gas is an inert gas, meaning that it does not react with other substances, which makes it perfect for use in applications where a non-reactive atmosphere is required. This includes the preservation of food products such as coffee, nuts, and crisps, where the use of nitrogen gas can help keep the products fresh for a longer period.Nitrogen gas is also used extensively in the oil and gas industry. It is used to provide an inert atmosphere for drilling operations, as well as in oil and gas refining processes. With the increasing popularity of shale gas extraction methods, the demand for nitrogen gas in the oil and gas industry is only set to increase further.Another industry that has seen a significant increase in demand for nitrogen cylinders is the medical sector. Nitrogen gas is used extensively in medical procedures, including cryotherapy, where it is used to cool and freeze unwanted tissue. The use of nitrogen gas in the medical sector has grown exponentially in recent years, leading to increased demand for nitrogen cylinders from companies such as {Company Name}.Despite the many benefits of using nitrogen cylinders, there are some concerns regarding the transportation of these potentially hazardous items. However, {Company Name} has taken every measure to ensure that their cylinders are safe, reliable, and meet all relevant industry standards.All cylinders produced by {Company Name} are manufactured using high-quality materials and are subject to rigorous testing to ensure that they meet strict safety standards. The company also provides comprehensive user manuals and guidelines to ensure that their cylinders are used safely and properly by their customers.In conclusion, nitrogen cylinder sizes have become increasingly popular across a wide range of industries. Companies such as {Company Name} have seen a surge in demand for their products, which are trusted by their customers for their reliability, safety, and affordability. With the versatile application of nitrogen gas across various industries, the use of nitrogen cylinders is only set to grow further in the coming years.

Meet the Next Generation Cryogenic Reservoir: A Breakthrough in Sustainable Energy Storage

Title: Advancing Cryogenic Storage Technology: A Cutting-Edge Solution for Enhanced Reservoir EfficiencySubtitle: {Company Introduction} revolutionizes cryogenic storage with innovative reservoir solutionsIntroduction:Advancements in the field of cryogenic technology are continuously creating waves across numerous industries, especially in the realm of energy and storage. One company, {Company}, has emerged as a pioneer, revolutionizing the way cryogenic storage is approached with their advanced reservoir solutions. By harnessing the power of cryogenics, combined with their expertise, {Company} is poised to enhance reservoir efficiency to unprecedented heights.The Cryogenic Reservoir Revolution:The evolution of cryogenic reservoirs has paved the way for groundbreaking technology capable of maximizing storage capacity, minimizing energy loss, and improving overall system efficiency. With their commitment to innovation, {Company} has developed a state-of-the-art cryogenic reservoir, which not only pushes the boundaries of traditional storage solutions but also sets new industry standards.Energy Efficiency and Reliability:One of the key features that distinguishes {Company}'s cryogenic reservoir is its exceptional energy efficiency. The insulation materials and advanced construction techniques employed ensure minimal heat transfer, thereby reducing energy consumption. By maintaining extremely low temperatures, this cutting-edge technology minimizes the risk of temperature fluctuations and energy loss, guaranteeing reliable and efficient storage for a wide range of applications.Safety and Durability:{Company} places paramount importance on safety and durability. Their cryogenic reservoirs are constructed using premium materials that can withstand extreme operating conditions. Rigorous testing and quality control procedures ensure that each reservoir meets the highest safety standards, making them suitable for a variety of harsh environments, including industrial, energy, and scientific research settings.Applications and Benefits:The applications of {Company}'s cryogenic reservoirs are vast and impactful. They can be employed in natural gas liquefaction and storage facilities, providing a secure and efficient means to handle and store vast quantities of liquefied natural gas (LNG). Additionally, the reservoirs are instrumental in the storage and transportation of cryogenic gases used in medical applications, aerospace, and energy distribution networks, among others.The benefits of incorporating {Company}'s cryogenic reservoirs are manifold. Through their innovative design, these reservoirs offer increased storage capacity, allowing for greater flexibility and scalability in addressing growing storage demands. Moreover, the reduced energy loss and enhanced efficiency deliver significant cost savings for businesses, making them an economically advantageous solution for industries heavily reliant on cryogenic storage.Environmental Sustainability:As the world grapples with the challenges of climate change, the need for sustainable solutions in energy and storage becomes imperative. {Company}'s cryogenic reservoirs align seamlessly with global efforts to minimize carbon emissions. By facilitating the storage and use of cleaner fuels and renewable energy sources, these reservoirs contribute to the transition towards a greener and more sustainable future.Concluding Remarks:{Company}'s introduction of advanced cryogenic reservoir technology marks a significant milestone in the field of storage and energy. With their innovative solutions, they have enabled businesses and industries to optimize storage capacity, enhance system efficiency, and reduce environmental impact. As the demand for cryogenic storage continues to grow, {Company}'s pioneering efforts in this sector are undeniably transforming the industry landscape, opening up infinite possibilities for the future.

Cryogenic Storage Tank: Latest Advancements and Uses in Industry

Cryogenic storage tanks are a critical component in a variety of industries, including healthcare, food and beverage, and manufacturing. These tanks are used to store and transport cryogenic gases at extremely low temperatures, making them essential for preserving biological materials, transporting liquefied natural gas, and conducting scientific research.One company at the forefront of cryogenic storage tank technology is {Company}. With over 100 years of experience in the industrial gas industry, {Company} is a global leader in providing technology and engineering solutions for a wide range of applications. Their expertise in cryogenic storage tanks has positioned them as a trusted partner for businesses looking to safely and efficiently store and transport cryogenic gases.{Company}'s cryogenic storage tanks are designed to meet the highest safety and performance standards. They offer a variety of tank designs that can accommodate different volume capacities and operational requirements. Whether it's for industrial gas storage, medical applications, or LNG transportation, {Company}'s cryogenic storage tanks are engineered to deliver reliable and efficient performance.One of the key elements that sets {Company}'s cryogenic storage tanks apart is their advanced insulation technology. Cryogenic gases need to be stored at extremely low temperatures to remain in their liquid state, and proper insulation is crucial for maintaining these temperatures. {Company}'s tanks are equipped with state-of-the-art insulation systems that minimize heat transfer and ensure that the stored gases remain at the desired temperature, reducing the risk of product loss or damage.In addition to their innovative design and engineering, {Company}'s cryogenic storage tanks are also equipped with advanced safety features. These include pressure relief devices, emergency venting systems, and leak detection technology. These safety measures are essential for preventing accidents and ensuring that the stored cryogenic gases are handled and stored in compliance with industry regulations and best practices.Another key strength of {Company}'s cryogenic storage tanks is their commitment to sustainability. As an industry leader, {Company} is dedicated to developing technologies and solutions that minimize environmental impact and promote sustainable practices. Their cryogenic storage tanks are designed to optimize energy efficiency, reduce greenhouse gas emissions, and minimize waste, making them an attractive choice for businesses seeking to enhance their environmental performance.{Company}'s cryogenic storage tanks have been deployed in a wide range of applications, from LNG terminals to medical facilities, and have consistently demonstrated their reliability, safety, and performance. With a global network of manufacturing and service facilities, {Company} is able to provide comprehensive support and assistance to customers around the world, ensuring that their cryogenic storage tanks are properly installed, maintained, and serviced.Looking ahead, {Company} continues to invest in research and development to further enhance the performance and capabilities of their cryogenic storage tanks. With a focus on innovation and continuous improvement, {Company} is well positioned to meet the evolving needs of industries that rely on cryogenic gases, offering cutting-edge solutions that deliver exceptional value and reliability.In conclusion, {Company}'s cryogenic storage tanks represent a significant advancement in the safe and efficient handling of cryogenic gases. With their proven track record, commitment to sustainability, and ongoing investment in technology and innovation, {Company} is poised to remain a leader in the cryogenic storage tank industry, providing customers with solutions that meet the highest standards of quality, safety, and performance.

Cryogenic Bulk Tanks: Latest Innovation in Cold Storage Technology

Cryogenic Bulk Tanks are Revolutionizing the Storage and Transportation of Industrial GasesAs the demand for industrial gases continues to grow, the need for reliable and efficient storage and transportation solutions has become increasingly important. Cryogenic bulk tanks have emerged as a game-changing technology in this industry, providing a safe and cost-effective way to store and transport a wide range of gases, including oxygen, nitrogen, and argon.One company that is leading the way in this space is [Company Name]. With decades of experience in the design and manufacturing of cryogenic equipment, [Company Name] has established itself as a trusted partner for businesses across the globe. Their commitment to innovation and quality has made them a go-to choice for companies in a wide range of industries, including healthcare, manufacturing, and aerospace."Cryogenic bulk tanks are an essential part of our product portfolio, and we are proud to offer our customers some of the most advanced and reliable solutions on the market," said [Company Name] CEO, [CEO Name]. "We understand the critical role that these tanks play in our customers' operations, and we are dedicated to providing them with the best possible products and service."One of the key advantages of cryogenic bulk tanks is their ability to store large quantities of gas in a relatively small footprint. This makes them an ideal solution for businesses that need to maximize their storage capacity while minimizing the space requirements. Additionally, the tanks are designed to maintain precise temperature and pressure levels, ensuring the safe and efficient storage of gases over extended periods.In terms of transportation, cryogenic bulk tanks offer a number of significant benefits. Their robust construction and advanced insulation technology make them well-suited for long-distance transportation, even in harsh environmental conditions. This allows businesses to safely and reliably transport large volumes of gases to their customers, regardless of the distance or climate.[Company Name] offers a diverse range of cryogenic bulk tanks to meet the specific needs of their customers. Whether it's a small-scale operation or a large industrial facility, their team of experts works closely with each customer to design and customize a solution that perfectly fits their requirements. From horizontal to vertical tanks, and from stationary to transportable options, [Company Name] offers a comprehensive range of products that can be tailored to meet any challenge.Furthermore, [Company Name] provides a full suite of services to support their customers, from installation and commissioning to ongoing maintenance and support. Their team of specialists is available to offer expert advice and assistance at every stage of the project, ensuring that their customers get the most out of their investment in cryogenic bulk tanks.In addition to their commitment to quality and innovation, [Company Name] places a strong emphasis on safety and regulatory compliance. All of their cryogenic bulk tanks are designed and manufactured to the highest industry standards, and they undergo rigorous testing and inspection processes to ensure their reliability and performance. This gives their customers the peace of mind that they are investing in a product that meets the most stringent safety and quality requirements.Looking ahead, [Company Name] is continuing to push the boundaries of cryogenic technology, with ongoing research and development efforts aimed at further enhancing the performance and efficiency of their bulk tanks. With a focus on sustainability and environmental responsibility, they are also exploring new ways to minimize the environmental impact of their products, while maximizing their overall benefits to businesses and society.In conclusion, cryogenic bulk tanks have become an indispensable tool for businesses that rely on the safe and efficient storage and transportation of industrial gases. With [Company Name] at the forefront of this industry, businesses can be confident that they have a reliable and innovative partner to support their needs for decades to come.