New 3D Model of Nitrogen Released: Learn More Here

By:Admin

In a groundbreaking development, a cutting-edge nitrogen 3D model has been introduced to the manufacturing industry, promising to revolutionize the way products are designed and produced. The state-of-the-art technology, developed by a leading company in the field of additive manufacturing, is set to redefine the manufacturing process and open up new possibilities for businesses across various sectors.

The nitrogen 3D model, which offers unparalleled precision and efficiency, is the result of years of research and innovation. It leverages the latest advancements in additive manufacturing to create highly detailed and intricate objects with unprecedented speed and accuracy. This game-changing technology has the potential to streamline the production process, reduce costs, and expand the scope of what can be achieved in the realm of manufacturing.

With the introduction of the nitrogen 3D model, businesses will be able to harness the power of additive manufacturing in a way that was previously unimaginable. The technology enables the creation of complex geometric shapes and structures that would be impractical or impossible to produce using traditional methods. This opens up new design possibilities and allows for the development of innovative products that were once deemed unattainable.

Furthermore, the nitrogen 3D model offers significant benefits in terms of production efficiency and cost-effectiveness. By utilizing advanced additive manufacturing techniques, the technology can significantly reduce the time and resources required to produce high-quality products. This not only accelerates the manufacturing process but also enables businesses to bring new products to market faster and more efficiently than ever before.

In addition to its technical capabilities, the nitrogen 3D model is designed with user-friendliness and accessibility in mind. The technology is equipped with intuitive software and user interfaces, making it easy for designers and engineers to create and manipulate 3D models with precision and ease. This ensures that businesses can fully harness the potential of additive manufacturing without the need for extensive training or technical expertise.

As a leading company in the additive manufacturing industry, the company behind the nitrogen 3D model is committed to pushing the boundaries of what is possible in manufacturing. With a proven track record of innovation and excellence, the company has positioned itself at the forefront of additive manufacturing technology, constantly setting new industry standards and pushing the envelope of what is achievable in the realm of 3D printing.

The introduction of the nitrogen 3D model represents a major milestone for the company, demonstrating its continued dedication to delivering cutting-edge solutions that drive progress and innovation in the manufacturing industry. By combining advanced technology with a deep understanding of the needs and challenges facing businesses, the company has positioned itself as a trusted partner for organizations looking to embrace the future of manufacturing.

In conclusion, the introduction of the nitrogen 3D model heralds a new era in additive manufacturing, offering businesses unprecedented capabilities and opportunities to innovate and excel. With its advanced technology, user-friendly interface, and commitment to excellence, the nitrogen 3D model has the potential to transform the way products are designed and manufactured, opening up new frontiers for businesses across various industries. As additive manufacturing continues to evolve and advance, the company remains at the forefront, driving progress and shaping the future of manufacturing.

Company News & Blog

Cryogenic Tank for Ln2: All You Need to Know

The LN2 cryogenic tank has revolutionized the way that companies store and transport materials at extremely low temperatures. This innovative technology has many applications across a variety of industries, from medical research to food processing. The LN2 cryogenic tank is designed to keep materials at temperatures as low as -320 degrees Fahrenheit, allowing for long-term storage and transportation of perishable goods and biological samples.The LN2 cryogenic tank is produced by a leading company in the field of cryogenic technology. With over 50 years of experience in the industry, this company has a proven track record of producing high-quality, reliable cryogenic equipment. The company's dedication to innovation and customer satisfaction has made them a trusted name in the field of cryogenics.The LN2 cryogenic tank is constructed using state-of-the-art materials and manufacturing techniques, ensuring that it is both durable and efficient. The tank is equipped with advanced insulation to minimize heat transfer, as well as safety features to prevent pressure build-up. This combination of cutting-edge technology and stringent quality control measures ensures that the LN2 cryogenic tank is fully capable of meeting the demands of modern industry.One of the key features of the LN2 cryogenic tank is its versatility. It can be used for a wide range of applications, from preserving biological samples in medical research facilities to freezing and transporting food products. The tank's large storage capacity and ability to maintain ultra-low temperatures make it an indispensable tool for companies operating in diverse industries.In the medical field, the LN2 cryogenic tank is used to store and transport biological samples, such as blood and tissue samples, as well as vaccines and other pharmaceutical products. The ability to maintain these materials at ultra-low temperatures is crucial for preserving their integrity and effectiveness. The LN2 cryogenic tank provides a reliable solution for medical facilities looking to safely store and transport these sensitive materials.In the food industry, the LN2 cryogenic tank is used for flash freezing and transporting perishable goods. This process helps to maintain the quality and freshness of the food products, as well as extend their shelf life. Whether it's transporting seafood from the fishing boat to the processing plant or delivering ice cream from the factory to the supermarket, the LN2 cryogenic tank ensures that these products are kept at their optimal temperature during transit.The LN2 cryogenic tank is also used in research and development, where it plays a vital role in various scientific experiments and studies. Its ability to maintain ultra-low temperatures makes it an essential tool for researchers working with sensitive materials, such as cell cultures and genetic samples. The tank's reliability and precision make it an invaluable asset in the pursuit of scientific discovery.Overall, the LN2 cryogenic tank has proven to be a game-changer in the field of cryogenic technology. Its advanced design, reliability, and versatility have made it an indispensable tool for companies operating in a wide range of industries. As the demand for ultra-low temperature storage and transport continues to grow, the LN2 cryogenic tank is poised to play an increasingly important role in shaping the future of these industries. With its proven track record and commitment to innovation, the company behind the LN2 cryogenic tank is well-positioned to continue leading the way in cryogenic technology for years to come.

Durable 1000 Ltr Steel Tank for Industrial Use

Steel Tank 1000 Ltr, a leading manufacturer of industrial storage tanks, has recently launched a new line of 1000-liter steel tanks designed to meet the growing demand for high-quality storage solutions in various industries. With a focus on durability, reliability, and customization, Steel Tank 1000 Ltr is set to revolutionize the way businesses store and transport liquids.Founded in 1995, Steel Tank 1000 Ltr has established itself as a trusted name in the industrial tank manufacturing industry. The company's state-of-the-art facilities and cutting-edge technology enable them to produce top-of-the-line storage solutions that meet the diverse needs of their clients. With a dedicated team of engineers, designers, and production staff, Steel Tank 1000 Ltr is committed to delivering superior products that exceed industry standards.The new 1000-liter steel tanks from Steel Tank 1000 Ltr are designed to provide a safe and reliable storage solution for various liquids, including industrial chemicals, petroleum products, and water. Constructed from high-quality, corrosion-resistant steel, these tanks are built to withstand harsh environmental conditions and provide long-term performance. Each tank is meticulously engineered to meet stringent quality control standards, ensuring that it meets the highest level of safety and reliability.In addition to their exceptional durability, Steel Tank 1000 Ltr's 1000-liter steel tanks also offer a high degree of customization. Clients have the option to choose from a range of accessories and fittings to tailor the tank to their specific requirements. This level of flexibility allows businesses to optimize their storage solutions and maximize efficiency in their operations."We are thrilled to introduce our new line of 1000-liter steel tanks to the market," said a spokesperson for Steel Tank 1000 Ltr. "These tanks represent the culmination of years of research, development, and innovation. We believe they will set a new standard for industrial storage solutions and provide our clients with a reliable, long-lasting, and cost-effective option for their liquid storage needs."Steel Tank 1000 Ltr's dedication to quality and innovation has made them a preferred partner for businesses across a wide range of industries, including manufacturing, agriculture, chemical processing, and more. With a focus on customer satisfaction and a commitment to excellence, the company has earned a reputation for delivering superior products and exceptional service.The launch of the new 1000-liter steel tanks is expected to further solidify Steel Tank 1000 Ltr's position as a leader in the industrial tank manufacturing industry. With their unwavering dedication to quality, reliability, and customization, the company continues to push the boundaries of what is possible in the world of industrial storage solutions.As businesses increasingly seek efficient and reliable storage solutions for their liquid products, the demand for high-quality industrial tanks continues to rise. Steel Tank 1000 Ltr is well-positioned to meet this demand with their innovative new line of 1000-liter steel tanks. With their proven track record of excellence and commitment to customer satisfaction, the company is poised to shape the future of industrial storage solutions for years to come.

Top Shipper Company Profile: What You Need to Know

The global shipping and logistics industry is a vital component of the modern economy, facilitating the movement of goods and products across the world. One of the key players in this industry is a leading shipper company, which has established itself as a reliable and efficient partner for businesses looking to transport their goods across the globe. With a strong focus on customer satisfaction, innovation, and sustainability, the company has become a trusted name in the shipping and logistics sector.Founded in [year], the company has grown to become a major player in the global shipping industry. The company's extensive network of shipping routes and strategic partnerships with key players in the industry have allowed it to provide comprehensive and efficient shipping solutions to its customers. Whether it's shipping goods by sea, air, or land, the company offers a wide range of services to meet the diverse needs of its clients.With a strong emphasis on innovation, the company has leveraged the latest technologies and industry best practices to streamline its operations and provide cost-effective solutions for its customers. From advanced tracking and monitoring systems to state-of-the-art warehousing and distribution facilities, the company has invested in cutting-edge infrastructure to ensure that its customers' goods are handled with the utmost care and efficiency.In addition to its commitment to innovation, the company is also dedicated to sustainability and environmental responsibility. The company has implemented a range of measures to minimize its environmental impact, including the use of eco-friendly packaging materials, optimizing shipping routes to reduce fuel consumption, and investing in energy-efficient technologies. By prioritizing sustainability, the company aims to contribute to a greener and more sustainable shipping industry.The company's dedication to customer satisfaction is evident in its customer-centric approach to business. The company's team of experienced and highly skilled professionals works closely with each customer to understand their unique shipping needs and to develop tailored solutions that meet their requirements. From small businesses to multinational corporations, the company has a proven track record of delivering reliable and efficient shipping services to a diverse range of clients.In line with its commitment to customer satisfaction, the company also places a strong emphasis on transparency and communication. The company provides regular updates and real-time tracking information to its customers, ensuring that they are informed every step of the way. This commitment to transparency and communication has earned the company a reputation for reliability and trustworthiness in the industry.As the global shipping and logistics industry continues to evolve, the company remains at the forefront, adapting to new trends and technologies to meet the changing needs of its customers. With a strong focus on customer satisfaction, innovation, and sustainability, the company is well-positioned to continue its growth and success in the years to come.In conclusion, the leading shipper company has established itself as a reliable and efficient partner for businesses looking to transport their goods across the globe. With a strong emphasis on customer satisfaction, innovation, and sustainability, the company has become a trusted name in the shipping and logistics sector. By leveraging the latest technologies, implementing sustainable practices, and maintaining a customer-centric approach to business, the company is well-equipped to meet the diverse and evolving needs of its clients in the global shipping industry.

Container Manufacturer in Germany - Container Sales and Trading Across Europe | Mobile Hybrid Containers for COVID-19 Vaccines | Buy New or Used Sea Containers Worldwide | Tractors for Internal Transport | Insulated Storage Containers | Discounted Construction Site Containers | 20ft Flat Rack Containers

In response to the COVID-19 pandemic, German company MECOTEC Group has launched a one-stop solution for the transport, storage, and distribution of vaccines with its first Mobile Hybrid Container. This innovative product offers deep-freeze capabilities and can be easily transported to different locations. For those in need of storage or transport containers, several companies offer a variety of options. SCHÄFER Container Systems is a major container manufacturer while HaCoBau - Hallen- und Containersysteme GmbH offers a range of products including material and insulated storage containers. Sea and Shipping Containers provides new and used sea containers worldwide, and MT Container offers flats, building, and discount containers. For internal transport in seaports, industry, logistics, and distribution centers, MAFI Transport-Systeme GmbH produces tractors while CONTAINEX provides sea containers. In summary, there is a wide array of options for those needing containers for storage, transport, or even specialized products like the MECOTEC Mobile Hybrid Container that can facilitate vaccine distribution. Whether you need standard sea containers, insulated storage containers, or building and flat containers, there are many options to choose from.

Dewar Receives CE Certification for Product

The CE certification of {brand} dewar (need remove brand name) is a significant achievement for the company, showcasing its commitment to producing high-quality, safe, and reliable products. This certification is a testament to the company's dedication to meeting the stringent requirements set forth by the European Union for ensuring the safety and performance of medical equipment.{Company} is a leading manufacturer of medical and laboratory equipment, specializing in the production of dewars, which are used for the storage and transportation of biological samples, vaccines, and other temperature-sensitive materials. The company has built a reputation for delivering innovative solutions that meet the evolving needs of the healthcare and research industries.With the CE certification now in place, {company} can further expand its reach in the European market, offering its customers the assurance that its dewars meet the highest standards for safety and performance. This certification also opens up new opportunities for the company to collaborate with healthcare institutions and research facilities across Europe, providing them with reliable and efficient storage solutions for their critical materials.To obtain the CE certification, {company} had to undergo a rigorous evaluation of its dewar products, including an assessment of their design, manufacturing process, and compliance with regulatory requirements. This involved thorough testing and inspection to ensure that the products meet the European Union's strict safety and performance standards. The successful completion of this certification process is a testament to the company's unwavering commitment to delivering products of the highest quality and reliability.In addition to meeting the requirements for CE certification, {company} also adheres to international standards for quality management, environmental sustainability, and occupational health and safety. The company's dedication to upholding these standards underscores its responsibility to its customers, employees, and the environment.The CE certification of {brand} dewar serves as a validation of {company}'s ongoing efforts to prioritize excellence and customer satisfaction. The company's continued investment in research and development, as well as its emphasis on quality control and regulatory compliance, positions it as a trusted partner for healthcare and research professionals seeking dependable storage solutions.In response to this achievement, {company} expressed its gratitude to the team of experts who contributed to the certification process, as well as its customers and partners who have continued to place their trust in the company's products and services. {Company} remains committed to upholding the highest standards of quality and safety, and the CE certification of its dewars is a testament to this dedication.Looking ahead, {company} is poised to leverage the momentum of this certification to further innovate and expand its product offerings. The company's focus on meeting the evolving needs of the healthcare and research industries will continue to drive its development of advanced storage solutions that prioritize safety, reliability, and efficiency.In conclusion, the CE certification of {brand} dewar is a significant milestone for {company}, solidifying its position as a leading provider of high-quality, safe, and reliable storage solutions for the healthcare and research sectors. With this certification in place, {company} is well-positioned to build upon its success and continue its legacy of excellence in the industry.

Top-quality solid liquid nitrogen tank for sale in the US

U.S. Solid, a leading provider of high-quality laboratory and industrial equipment, has recently announced the launch of their new liquid nitrogen tank designed to meet the needs of a wide range of applications in the scientific and industrial fields. With a reputation for delivering reliable and innovative solutions, U.S. Solid has once again proven their commitment to excellence with the introduction of this cutting-edge product.The liquid nitrogen tank, which comes in various sizes to suit different requirements, is constructed with premium-grade materials to ensure durability and safety. It is designed to store and dispense liquid nitrogen efficiently, making it an essential tool for applications such as cryogenic storage, laboratory research, medical procedures, and industrial processes. The tank is equipped with advanced features that enable precise control of the liquid nitrogen flow, as well as secure storage to prevent leaks or spills.One of the key advantages of the U.S. Solid liquid nitrogen tank is its versatility and adaptability to diverse environments. Whether it is used in a laboratory setting for scientific research or in an industrial facility for manufacturing processes, this tank is engineered to perform with utmost reliability and efficiency. Its user-friendly design and practical functionalities make it a valuable asset for professionals in various fields who rely on precise and safe handling of liquid nitrogen.The company's dedication to quality and innovation is evident in the meticulous engineering and rigorous testing that went into the development of the liquid nitrogen tank. U.S. Solid has a team of experienced engineers and technicians who are committed to delivering products that meet the highest standards of performance and safety. As a result, customers can have full confidence in the reliability and effectiveness of this new addition to the U.S. Solid product line.In addition to the exceptional quality of the liquid nitrogen tank, U.S. Solid also offers comprehensive customer support and technical assistance to ensure that users can maximize the benefits of this product. Their team of experts is available to provide guidance on installation, operation, and maintenance, as well as to address any inquiries or concerns that customers may have. This level of support reflects U.S. Solid's dedication to fostering strong and enduring relationships with their clients.Furthermore, the company's commitment to environmental sustainability is reflected in the design of the liquid nitrogen tank, which is engineered to minimize energy consumption and reduce waste. U.S. Solid recognizes the importance of responsible and eco-friendly practices in today's world, and they have integrated these principles into their product development process. By choosing the U.S. Solid liquid nitrogen tank, customers can contribute to a greener and more sustainable future.Overall, the introduction of the U.S. Solid liquid nitrogen tank represents another milestone in the company's ongoing mission to provide cutting-edge solutions that empower professionals in the scientific and industrial sectors. With its superior performance, practical design, and comprehensive support, this product sets a new standard for the storage and dispensing of liquid nitrogen. As U.S. Solid continues to innovate and expand their product offerings, customers can expect even more groundbreaking solutions to meet their evolving needs.In conclusion, the U.S. Solid liquid nitrogen tank is a testament to the company's unwavering commitment to excellence, quality, and customer satisfaction. With its advanced features, versatility, and environmental consciousness, this product has already garnered attention and praise from professionals across various industries. As U.S. Solid continues to lead the way in delivering innovative solutions, the liquid nitrogen tank stands as a prime example of their dedication to advancing the capabilities of scientific and industrial applications.

EU Pressure to Increase Transparency in Liner Companies Gives Shippers Hope

Shipping companies are increasingly facing pressure from shippers to become more transparent in their operations. This is because many shippers feel that they do not have enough information about what is happening with their cargo when it is being transported by these companies.One of the main concerns for shippers is the concentration of power among liner companies. This is making it difficult for them to negotiate favourable deals and prices. They also feel that this concentration is leading to less competition, which is affecting the quality of service they receive.Shippers are now hoping that the EU can help to force through changes in the industry. Specifically, they are calling for more transparency and accountability from shipping companies. This would include things like more detailed tracking of shipments and better communication with customers.In order to achieve this, shippers are calling for the introduction of mandatory regulations that would require liner companies to provide more information about their operations. They are also calling for more competition in the industry, which would force companies to improve their services in order to stay competitive.One area where shippers are particularly concerned is the use of dry shipper containers. These containers are designed to keep goods dry during transport, but there is concern that they are not always being used properly. Shippers are calling for more information about how these containers are being used and what measures are being taken to ensure that they are working correctly.Overall, shippers are calling for a more open and transparent industry. They believe that this will not only benefit them, but also the shipping companies themselves. By providing better information and services, these companies will be able to build stronger relationships with their customers and improve their bottom line.

New Food Trend: Use of Liquid Nitrogen in Culinary Techniques

Title: Groundbreaking Application of Advanced Cryogenic Technology Revolutionizes Multiple IndustriesIntroductionIn an era of technological breakthroughs, Company X has managed to spearhead a new era by harnessing the power of advanced cryogenic technology. Through their latest innovation, Liquid Nitrogen (LN2), Company X has revolutionized a wide range of industries and opened up a myriad of possibilities for improved efficiency, productivity, and sustainability. This article will delve into the various applications of LN2 in different sectors, while providing an overview of the groundbreaking company behind this transformative technology.Company X - Leader in Cryogenic SolutionsCompany X is a pioneering force in the field of cryogenic technology, specializing in the development and application of LN2. With years of research and development behind them, they have emerged as a trusted name in providing innovative solutions to industries ranging from agriculture to healthcare. The company's commitment to research, safety, and efficient delivery systems has cemented their position as a market leader in the cryogenics industry.Liquid Nitrogen - The Game ChangerLiquid Nitrogen, a colorless and odorless cryogenic liquid, has been widely utilized for various applications across different sectors. Its extremely low temperature of -196 degrees Celsius (-321 degrees Fahrenheit) makes it an exceptional cooling agent and an ideal solution for managing a wide range of innovative processes.Agriculture and HorticultureThe use of LN2 in agriculture and horticulture has proven to be a game-changer, offering increased productivity and quality control. Farmers and growers are utilizing LN2 to quickly freeze crops after harvest, preserving their nutritional value without the need for chemical additives. Additionally, controlled nitrogen gas environments created using LN2 are extending the shelf life of fruits, vegetables, and other perishable products, reducing food waste and improving overall conservation efforts.Manufacturing and MachiningIn the realm of manufacturing, LN2 is facilitating improvements in precision machining and part production. Rapid cooling enables metals to harden quickly, reducing production time and increasing the longevity of the final products. Furthermore, LN2's use in cryogenic processing provides manufacturers with the ability to improve the wear resistance and strength of materials, leading to increased product durability, reliability, and cost-effectiveness.Healthcare and PharmaceuticalsLN2's ultra-low temperatures have found significant applications in the field of healthcare and pharmaceuticals. The technique of cryotherapy, involving freezing abnormal tissues or tumors, has gained traction as a minimally invasive treatment option, offering improved patient outcomes and reduced recovery time. In pharmaceuticals, LN2 facilitates the storage and transportation of biological samples and vaccines, ensuring their potency and efficacy, even in remote locations, thereby benefiting global healthcare initiatives.Food and Beverage IndustryThe food and beverage industry has embraced LN2 for its transformative qualities. Flash freezing with LN2 allows manufacturers to lock in the taste, texture, and nutritional value of food products at the peak of freshness. This method enables quick freezing, preserving the delicate properties of ingredients, and providing consumers with a superior sensory experience. Similarly, the use of LN2 in the production of beverages has gained popularity, enhancing flavors, reducing crystallization, and enabling the creation of unique and refreshing beverages.Environmental ConservationLN2 also contributes positively to environmental conservation efforts. Its ability to efficiently and effectively freeze and store biological materials, including animal and plant samples, aids in safeguarding genetic biodiversity. Moreover, the controlled nitrogen gas environments created by LN2 assist in mitigating the release of harmful gases into the atmosphere, aiding in the fight against climate change.ConclusionCompany X's remarkable innovation in the field of cryogenic technology, specifically with Liquid Nitrogen, is transforming industries across the board. Agriculture, manufacturing, healthcare, and the food and beverage industry are but a few sectors benefitting from the numerous advantages LN2 brings. As this cutting-edge technology continues to evolve, it holds the potential to further revolutionize processes, improve sustainability, and pave the way for a more efficient and advanced future across a multitude of industries.

Multiple Injuries Reported After Nitrogen Tank Explosion

On Friday, a nitrogen tank explosion occurred at the premises of a renowned manufacturing company in the heart of the industrial district. The explosion took place at the facility owned by the company, which specializes in the production of industrial equipment and machinery. The incident has raised concerns about workplace safety and has left the entire community in shock.The explosion caused significant damage to the manufacturing facility, with several parts of the building being severely affected. Authorities immediately responded to the incident, and the company's emergency response team also worked tirelessly to contain the situation and ensure the safety of all the employees.Thankfully, there were no reported injuries as a result of the explosion, which is a relief in light of the magnitude of the incident. The company has confirmed that all employees are safe and accounted for, and they are currently assessing the extent of the damage caused by the explosion.The manufacturing company, with a long-standing history in the industry, is known for its high-quality products and commitment to innovation. The facility where the explosion occurred is a crucial part of the company's operations, playing a key role in the production and assembly of their products.The company takes pride in its dedication to maintaining the highest standards of safety and quality in all aspects of its operations. It has implemented various safety protocols and measures to ensure the well-being of its employees and the protection of its facilities. The incident is being thoroughly investigated to determine the cause of the explosion and to prevent any future occurrences.In the aftermath of the explosion, the company expressed its gratitude for the swift response of the emergency services and the support of the community. They have also assured their customers and stakeholders that they are taking all necessary steps to resume their operations and minimize any impact on their production and supply chain.As news of the explosion spread, there has been an outpouring of support and solidarity from other businesses in the area, as well as from the local community. The company has been a major contributor to the economic growth and development of the region, and the incident has sparked a sense of collective concern for the well-being of all those involved.The incident serves as a stark reminder of the potential risks and hazards that are inherent in industrial operations. It also underscores the importance of robust safety measures and procedures to prevent such incidents from occurring. The company is committed to learning from this experience and strengthening its safety protocols to ensure the well-being of its employees and the integrity of its facilities.As the investigation into the explosion continues, the company is focused on rebuilding and restoring its operations. They are working closely with the relevant authorities to assess the damage and develop a plan for the restoration of the facility. The company is also providing support to its employees and ensuring that they have access to any necessary resources during this challenging time.In the face of this unexpected and unfortunate incident, the company remains resolute in its commitment to upholding the highest standards of safety and quality. They are determined to emerge from this incident stronger and more resilient, and they are grateful for the support and understanding of their customers, partners, and the community at large.

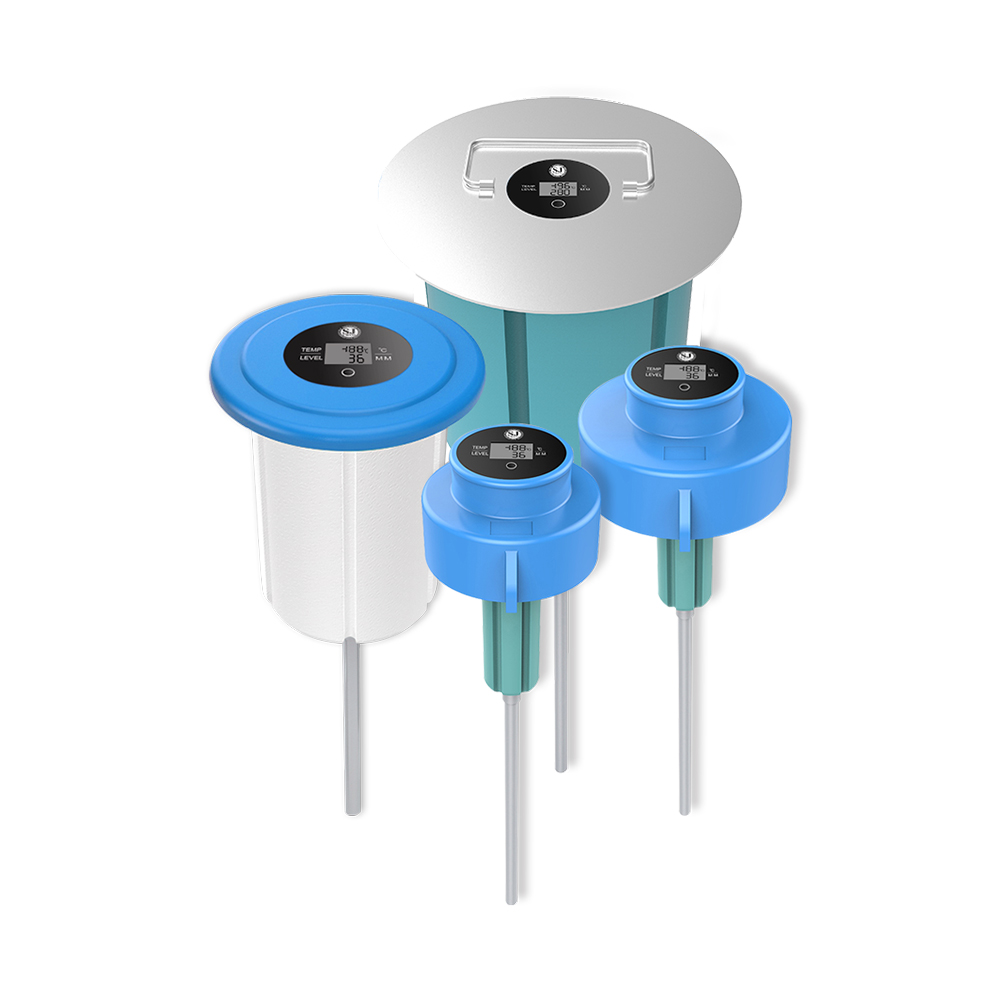

Smart Cryotherapy Controller: The Latest Advancement in Cryotherapy Technology

Introducing the Next Generation Cryogenic Control TechnologyIn the world of cryogenics, precision and accuracy are paramount. Whether it's for scientific research, medical applications, or industrial processes, the ability to maintain precise control over temperatures and pressures is essential. That's why the development of the new Cryosmart Controller from {company name} represents a significant advancement in cryogenic control technology.The Cryosmart Controller is a state-of-the-art device that offers unparalleled control and monitoring capabilities for cryogenic systems. With its advanced features and user-friendly interface, this controller is poised to revolutionize the way cryogenic systems are operated and managed.What sets the Cryosmart Controller apart from other similar devices on the market is its ability to combine precise temperature and pressure control with advanced monitoring and automation capabilities. This allows for a level of control and precision that was previously unattainable, making it an ideal solution for a wide range of cryogenic applications.With its innovative design and cutting-edge technology, the Cryosmart Controller is set to become the new standard in cryogenic control. Its combination of advanced features and user-friendly interface makes it well-suited for a wide range of applications, from research laboratories to industrial manufacturing.One of the key features of the Cryosmart Controller is its ability to provide real-time monitoring of temperature and pressure, allowing operators to have complete visibility and control over their cryogenic systems. This level of monitoring and control is essential for ensuring the safety and efficiency of cryogenic systems, making the Cryosmart Controller an invaluable tool for any operation.Another standout feature of the Cryosmart Controller is its advanced automation capabilities. With the ability to set predefined parameters and automatically adjust settings as needed, this controller streamlines the operation of cryogenic systems, reducing the need for constant manual intervention and allowing operators to focus on other critical tasks.In addition to its advanced control and monitoring capabilities, the Cryosmart Controller is also designed with ease of use in mind. Its intuitive interface and user-friendly design make it simple for operators to navigate and utilize its features, making it accessible to a wide range of users.The Cryosmart Controller is also designed to be highly adaptable, with the ability to easily integrate with existing cryogenic systems. This makes it a convenient and cost-effective solution for companies and organizations looking to upgrade their cryogenic control capabilities without having to invest in entirely new systems.{company name} is proud to be at the forefront of cryogenic control technology, and the development of the Cryosmart Controller is a testament to our commitment to innovation and excellence. With its advanced features and unparalleled performance, this controller is set to redefine the standards for cryogenic control.Overall, the Cryosmart Controller represents a significant leap forward in cryogenic control technology. Its advanced features, user-friendly interface, and unparalleled performance make it an ideal solution for a wide range of cryogenic applications. As the industry continues to evolve, the Cryosmart Controller from {company name} is poised to become the new standard for cryogenic control and monitoring.